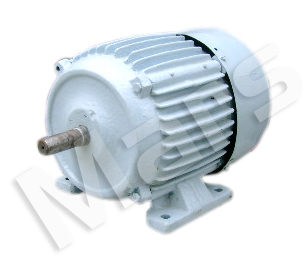

Squirrel cage induction motor

Product Details:

- Model No As per required specification

- Automation Grade Automatic

- Power Source AC Electric Power

- Temperature Range -15C to +50C (Ambient)

- Feature High Efficiency, Low Noise, Robust Construction, Easy Installation

- Core Components Stator, Rotor, Laminated Core

- Frequency 50 Hz

- Click to View more

Squirrel cage induction motor Product Specifications

- Depends on Capacity (e.g. 350 x 240 x 220 mm to 1500 x 850 x 950 mm)

- Varies with model (e.g. 30 kg to 900 kg)

- Automatic

- As per required specification

- Industrial, Pumps, Compressors, Blowers, Fans, Conveyors

- 50 Hz

- 415V 10%

- Three Phase Squirrel Cage Induction Motor

- Standard ratings available from 0.37 kW to 500 kW

- Cast Iron or Aluminium Body

- Stator, Rotor, Laminated Core

- -15C to +50C (Ambient)

- High Efficiency, Low Noise, Robust Construction, Easy Installation

- AC Electric Power

Product Description

Technical Specifications :

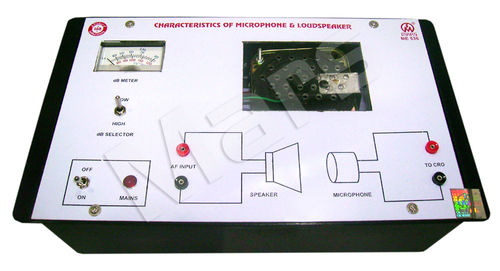

Meters : 3Nos. of Moving Coil Ammeter of Range 10 A AC of size 96*96mm provided on the front panel.

:1No. of Moving Coil Voltmeter of Range 500V AC of size 96*96mm provided on the front panel.

:1No. of Frequency Meter of Range 45-55 Hz of size 96*96mm provided on the front panel.

:1Nos. of Moving Coil Voltmeter of Range 300V DC of size 96*96mm provided on the front panel.

:1No. of Moving Coil Ammeter of Range 10 A DC of size 96*96mm provided on the front panel.

One No. of Star Delta starter of Range upto 10HP provided on the front panel.

One No. of Starter Switch provided on the Front Panel.

Three nos. of Kitkat Fuses of Range 16A provided on the front panel.

Three nos. of line indicators provided on the front panel.

Protection : 1No. of Miniature Circuit Breaker of Range 415V/

25 Amps (MCB/TPN) Provided on the Input Side.

Panel board of portable wooden panel box is in Tappered shape for better view angle.

Dimension (mm) : 787(L) x 254(B) x560(H)

Power Requirement : Three Phase 440V AC.

High Performance and Versatility

Our squirrel cage induction motors deliver robust performance, supporting a wide range of applications in industrial environments. With multiple poles (2/4/6/8), high efficiency (up to 95%), and broad voltage compatibility (415V 10%), these motors can be adapted to diverse operations, guaranteeing reliable torque and smooth speed control.

Superior Protection and Cooling

Equipped with enclosure types like Totally Enclosed Fan Cooled (TEFC) and Open Drip Proof (ODP), these motors provide effective resistance to contaminants and moisture. The air-cooled system with deep groove ball bearings ensures optimal temperature management, extending operational life even in challenging ambient temperatures up to 50C.

Easy Installation and Maintenance

Designed for straightforward foot or flange mounting, the motors offer simplified installation in various setups. Their low vibration and noise (below 75 dB) contribute to a safer and more comfortable working environment, while the rugged design minimizes service downtime.

FAQs of Squirrel cage induction motor:

Q: How does the totally enclosed fan cooled (TEFC) design benefit the motors operation?

A: The TEFC enclosure ensures the motor is protected from dust, moisture, and contaminants, enhancing reliability and reducing maintenance in demanding industrial environments. The built-in fan maintains optimal cooling, even when external airflow is limited.Q: What mounting options are available for these squirrel cage induction motors?

A: These motors offer both foot-mounted and flange-mounted configurations, allowing flexibility for different machinery layouts. Select the mounting style best suited to your installation and operational requirements.Q: When should I choose motors with higher insulation classes like Class F or Class H?

A: Higher insulation classes (Class F or H) are recommended if the motor will be regularly exposed to elevated temperatures or requires extended durability under thermal stress. They help prolong winding life in intensive duty cycles or hot ambient conditions.Q: Where can these motors be deployed effectively?

A: These motors are ideal for industrial settings such as pump stations, compressors, blowers, conveyors, and fans. Their rugged construction and versatile design make them suitable for use in manufacturing, processing, and utility sectors.Q: What is the process for starting these motors?

A: The motors support both Direct On Line (DOL) and Star-Delta starting methods, allowing for efficient and safe acceleration depending on your systems power demands and supply characteristics.Q: How does the motors high efficiency contribute to operational benefits?

A: With efficiencies up to 95% (complying with IE2/IE3 standards), these motors significantly reduce energy consumption and operating costs over time, making them a cost-effective solution for continuous industrial use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Electrical Machine Lab Equipments' category

|

Mars EdPal Instruments Pvt. Ltd.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |