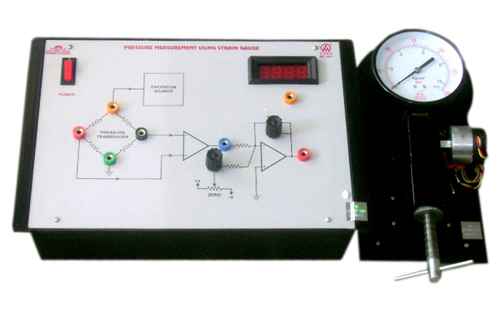

Pressure Measurement using Strain Gauge

Product Details:

- Measurement Range 0 to 10 kg/cm

- Capacity Up to 10 kg/cm

- Frequency 50 Hz

- Core Components Strain Gauge Sensor, Wheatstone Bridge, Pressure Chamber, Digital Display Unit

- Model No SGPM-6577

- Voltage 230V AC

- Accuracy 0.5% of F.S.

- Click to View more

X

Pressure Measurement using Strain Gauge Product Specifications

- 230V AC Supply

- Digital and Analog

- Direct Pressure Measurement, High Sensitivity, Calibration with Standard Weights

- Semi-Automatic

- 0C to 80C

- 0.5% of F.S.

- Approx. 7-10 kg

- Laboratory/Industrial Pressure Measurement

- Strain Gauge Sensor, Wheatstone Bridge, Pressure Chamber, Digital Display Unit

- 230V AC

- SGPM-6577

- 50 Hz

- Up to 10 kg/cm

- Mild Steel, Stainless Steel, Aluminum (as per model)

- Strain Gauge Based Pressure Transducer

- 0 to 10 kg/cm

- 450 mm x 250 mm x 200 mm

Product Description

Pressure Measurement using Strain Gauge

Objective : To measurement of Air Pressure using strain gauge. Specifications : A very good quality pressure sensor strain gauge based is used to measure the pressure and 3A12 digital display for pressure indicator. Range of pressure gauge is 0-10kg /cm2 and maximum capacity is 2kg /cm2 .A mechanical pressure pump with oil tank is used for apply the pressure This sensor forms a part of wheat stone bridge and with the help of signal conditioning provided in the panel measures air pressure with an accuracy of A2%. Power requirements 230V/50Hz.

Precision Pressure Measurement

Engineered with a Wheatstone bridge strain gauge sensor, the SGPM-6577 delivers outstanding accuracy of 0.5% of full scale. Its millivolt output provides high sensitivity, making it ideal for precise monitoring of air or fluid pressure. Both digital and analog displays ensure effortless readability for diverse operational preferences.

Robust and Versatile Construction

Constructed from high-quality stainless steel 304, this table-top pressure measurement unit ensures longevity and resistance to challenging industrial conditions. It supports a wide operating temperature (0C to 80C) and is protected to IP65 standards, suiting rigorous laboratory or shop-floor use in India and beyond.

Ease of Use and Calibration

The device features user-centric functions including manual zero adjustment and simple calibration with standard ISI certified weights. The 2-meter cable and compact dimensions (450 mm x 250 mm x 200 mm) facilitate convenient installation and operation in a variety of laboratory and industrial setups.

FAQ's of Pressure Measurement using Strain Gauge:

Q: How does the strain gauge-based pressure transducer measure pressure?

A: The SGPM-6577 utilizes a Wheatstone bridge strain gauge sensor to detect minute deformations caused by applied air or fluid pressure. These mechanical changes translate into millivolt bridge outputs, which are then read by the digital or analog display unit, providing accurate pressure readings.Q: What are the main benefits of using this pressure transducer for laboratory or industrial applications?

A: Its high accuracy (0.5% F.S.), fast response time (<150 ms), and direct digital or analog outputs make it ideal for environments requiring dependable and rapid pressure readings. The robust design ensures durability, while easy manual zero adjustment and calibration streamline regular use.Q: When should the device be calibrated and with what standard?

A: Calibration should be performed routinely or whenever precise accuracy is required. The process utilizes ISI certified weights, ensuring traceable and standardized pressure measurements for laboratory or industrial compliance.Q: Where can the SGPM-6577 be effectively installed?

A: Designed as a tabletop model with IP65 protection and sturdy construction, this transducer is well suited for laboratories, industrial plants, and quality control areas where reliable and direct pressure monitoring of air or fluids is essential.Q: What is the process for adjusting the zero point on the device?

A: Manual zero adjustment is accomplished using the dedicated control on the device, ensuring that baseline readings are accurate before commencing pressure measurements. This helps in maintaining consistency and reliability in results.Q: How does the device handle different environmental conditions?

A: The SGPM-6577 operates efficiently within 0C to 80C and up to 85% non-condensing humidity. Its IP65-rated enclosure and stainless steel construction enable stable and durable operation even in challenging laboratory or industrial environments.Q: What models or customizations are available for specific requirements?

A: The device can be configured with or without an internal amplifier, and is manufactured using mild steel, aluminum, or stainless steel components as per specified models or client requirements. These options allow for tailored solutions to suit various industrial or research applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

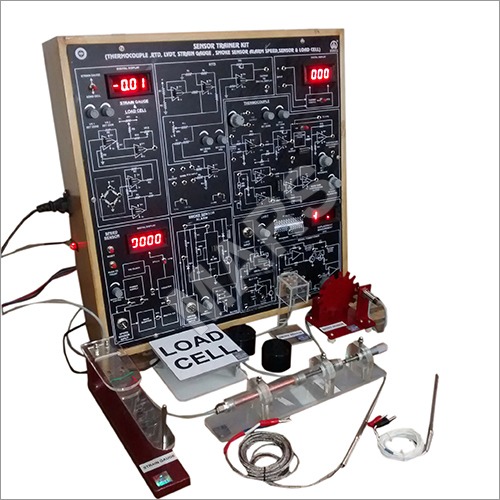

Other Products in 'Instrumentation Lab Equipments' category

|

Mars EdPal Instruments Pvt. Ltd.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |